All Right Machinery

PET bottle making technology

Affordable, Reliable, Flexible, Simple

Our Machines Make Your Own PET Bottles

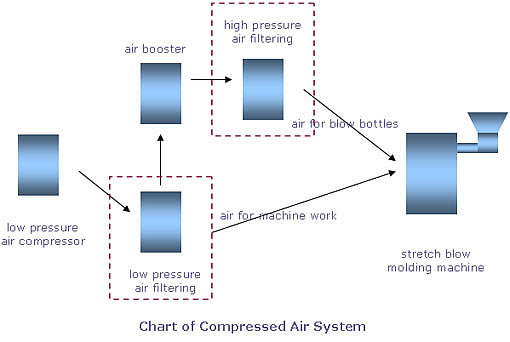

Air Cleaning System

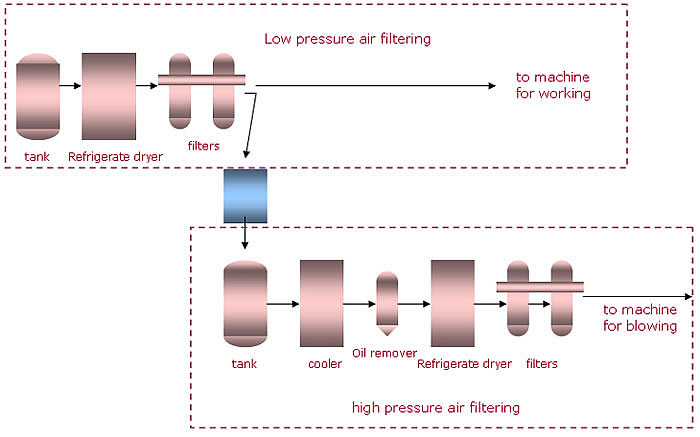

Look at the following chart. The air cleaning system can be break down to two parts, one for low pressure air filtering, another one for high pressure air filtering

The table below shows air cleaning parts that match the stretch blow machine:

Stretch Blow Machine |

Low pressure filtering

For machine working |

High pressure filtering

for bottle blowing |

1 x AL-2000 or 1x AL-3000 |

TCL(G)6.0/10G

6M3 /1.0Mpa/1.5KW |

TCHJ(Z)3.0/40

3 M3/4.0Mpa/0.75KW |

2x AL-2000 or 2xAL-3000 or 1xAL-2000 + 1xAL-3000 |

TCL(G)11/10G

11M3/1.0Mpa/2.5 KW |

TCHJ(Z)6.0/40

6 M3/4.0Mpa/1.5KW |

All units on the table are air cooled. No water will be required to cool them during operation. Water cooling models also available for selection.

Break down the models of above air cleaning parts:

- One automatic machine working

- TCL(G)6.0/10G - air comes from this cleaning system is good for machine working. It includes following items:

- One air tank 1.0/10 - 1M3, 1.0Mpa

- One air refrigerate dryer TCL(G)6.0/10 - 6M3, 1.0Mpa

- Two filters

- TCHJ(Z)3.0/40 - air from this cleaning system is good for blow bottles. It includes the following items.

- One air tank 0.6/40 - 0.6M3, 4.0Mpa

- One air cooler TCHL-3NF - 3M3/min,

- One oil remover TCCY

- One air refrigerate dryer TCL(G)3/40G - 3M3/min, 4.0Mpa

- Two filters

- TCL(G)6.0/10G - air comes from this cleaning system is good for machine working. It includes following items:

- Two automatic machines working

- TCL(G)11/10G includes - air comes from this cleaning system is good for machine working. It includes following items:

- One air tank 2.0/10 - 2M3, 1.0Mpa

- One air refrigerate dryer TCL(G)11/10 - 10M3, 1.0Mpa

- Two filters

- TCHJ(Z)6.0/40 - air from this cleaning system is good for blow bottles. It includes the following items.

- One air tank 1.0/40 - 1M3, 4.0Mpa

- One air cooler TCHL-6NF - 6M3/min,

- One oil remover TCCY

- One air refrigerate dryer TCL(G)6/40G - 6M3/min, 4.0Mpa

- Two filters

- TCL(G)11/10G includes - air comes from this cleaning system is good for machine working. It includes following items:

Further cleaning is made on the compressed air goes to machine for bottle blowing. The quality of air for blowing bottles reaches to dew point -26°C, articles < 0.01µm, oil < ppm and smell free.

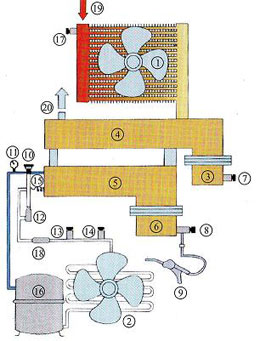

Enhanced Refrigerate Air Dryer

|

|

1 |

Pre cooling |

2 |

Refrigerate condenser | ||

3 |

Pre filter | ||

4 |

Cooler | ||

5 |

Vaporizer | ||

6 |

Filter | ||

7 |

Drainer 1 | ||

8 |

Drainer 2 | ||

9 |

Maintenance tooling | ||

10 |

Low pressure protective switch | ||

11 |

Gauge | ||

12 |

Hot air bypass valve | ||

13 |

High pressure protective switch | ||

14 |

Compressor pressure switch | ||

15 |

Expansion valve | ||

16 |

Compressor | ||

17 |

Inlet gauge | ||

18 |

Drying filter | ||

19 |

Compressed air inlet | ||

20 |

Compressed air outlet |

Specifications of the enhanced refrigerate air dryer

Model |

TCL(G)1 1.0G |

TCL(G)1 3.0G |

TCL(G)1 6.0G |

TCL(G)1 11G |

Capacity m3/min |

1.0 |

3.0 |

6.0 |

11 |

Operating pressure |

1.0 - 6.0 Mpa(tailored to specific applications) |

|||

Inlet air temperature |

< 80°C |

|||

Coolant |

R22 |

|||

Compressor power |

0.75KW |

1.0KW |

2.0KW |

3.0KW |

Dimension cm |

80x50x98 |

95x56x108 |

140x65x118 |

170x65x118 |

Weight kg |

130 |

250 |

350 |

450 |

Air quality after treated |

Dew point -23°C, articles < 0.01µmm, oil < ppm |

|||