All Right Machinery

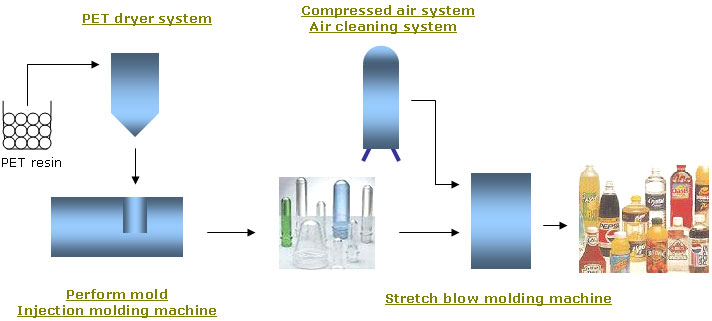

PET bottle making technology

Affordable, Reliable, Flexible, Simple!

Our Machines Make Your Designed PET Bottles Easy!

Why Two-Step Processing to make PET Bottles?

The answer is simple - Cost Effective and Flexibility

- Save Shipment Cost - Bottles (containers) take much more space than that of preforms. Many bottling companies have to consider to blow bottles by themselves than to buy bottles;

- Save Preform Mold - One preform design could blow countless designs of the bottles. By using two-step processing, one perform mold could supply many bottle blowers for different applications.

- Save Machine Cost - Preform making only machine and/or stretch blow-molding only machine is simpler to operate with less cost;

- Flexibility - Preforms could either be consumed to blow own use bottles or to resell. It is quite flexible for two-step processing;

- Preforms Standardization - This is no doubt a trend. Many standard performs are available in the market.

Two-Step PET Bottle Production Processing Chart