All Right Machinery

PET bottle making technology

Affordable, Reliable, Flexible, Simple

Our Machines Make Your Own PET Bottles

Air Compressor System

All stretch blow molding machines need clean compressed air to work and to blow PET bottles. There are some solutions of air compressor system for different operation conditions.

Solution 1 - High Pressure Air Compressor

There is built-in air pressure regulator in the machine. Partial of high pressure air will be automatic depressed to 7kg/cm² for machine operation while the remaining high pressure air (Max. 40kg/cm²) for blowing bottles. Or apply two air sources, the low pressure air compressor for machine operation, the high pressure air compressor for blowing bottles. For multi machine operation, it is recommended to build a central air compressor system. Below air compressors are options for single or two stretch blow molding machine operation.

| Model | Capacity M³/minute |

Max. Pressure kg/cm² |

Applications |

| HTA-140-II | 2 |

8 |

For 1 auto machine operation use only. |

| HTA-120X-I | 1 |

30 |

For 1 semi auto machine AL-III-2 or AL-III-5 |

| SSA-120 | 1.2 |

40 |

For 1 semi auto machine AL-III-2, AL-III-5, or AL-III-20 |

| SSA-155 | 2.2 |

40 |

For 2 semi auto machines, or 1 auto machine AL-3000S blowing only |

| STA-260 | 3 |

40 |

For 2 semi auto machines, or 1 auto machine AL-3000S blowing only |

| SSA-210 | 4 |

40 |

For 1 auto machine |

| 4xSSA-120 | 5 |

40 |

Consists of 4 SSA-120 air compressor, for 1 auto machine |

| 4xSSA-155 | 9 |

40 |

Consists of 4 SSA-155 air compressors. for 2 auto machines |

Main Specifications of Cylinder Air Compressor

Model |

Power KW |

Displacement M³/minute |

Pressure

|

Tank M³ |

Measurement mm |

HTA-140-II |

15 |

2.0 |

8 |

0.37 |

1825x760x1380 |

HTA-120X-I |

11 |

1.0 |

30 |

0.39 |

1800x700x1330 |

SSA-120 |

15 |

1.2 |

40 |

0.40 |

1810x745x1482 |

SSA-155 |

30 |

2.2 |

40 |

* |

1930x1000x1144 |

STA-260 |

37 |

3.0 |

40 |

* |

1980x1410x1370 |

SSA-210 |

55 |

4.0 |

40 |

* |

2080x1500x1600 |

4xSSA-120 |

60 |

5.0 |

40 |

* |

2150x1950x1600 |

4xSSA-155 |

120 |

9.0 |

40 |

* |

2451x2100x1700 |

* Air Tank is purchased separately.

** Compressed air has to be oil-free, water-free for blowing bottles and machine operation. It is highly recommended to use air filtration system to clean compressed air.

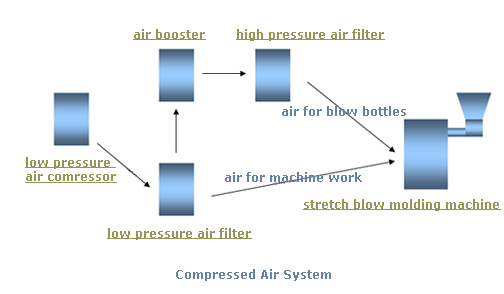

Solution 2 - Low Pressure air Compressor + Air Booster

Screw Air Compressor

SK series rotary screw air compressor incorporates PRATIKO PACK system from VMC S.P.A Italy. The system's intake valve uses VMC techniques with high reliability and durability. Its compact design which includes intake valve, minimum air pressure regulating valve, thermostatic temperature regulating valve, oil recovery system, safety valve and gear head as well as operation friendly touch-on LCD display make the system extremely integrated. Its PRACTIKO air/oil separator provides the compressed air with less than 1ppm oil that reduces its running cost significantly and saves regular services/maintenance greatly.

Air Booster

Air Booster, also named air amplifier, is for increasing air pressure for blowing PET bottles. Our stretch blow molding machine needs air pressure between 3.0 - 4.0mpa to blow bottles. Using air booster Z42W will provide you sufficient pressure to meet your need. This air booster equipped with patented Polygon Cylindrical Straight Flow Valve performances well at heavy duty, long load and extremely harsh conditions. The new technology,along with optimal profile valve blades, minimizes air flow impact on the valve, reduces flow resistance, thus saves energy up to 12% and lowers noise by 15% compare with conventional machines.

The models of the air compressor system can be selected from the table below:

Air Compressor |

Power kw |

Capacity m3/min |

Pressure mpa |

Air Booster |

Discharge Pressure mpa |

Power kw |

Capacity m3/min |

Machine(s) applicable |

SK37 |

37 |

5.6 |

1.0 |

Z42W |

5.0 |

22 |

3.0 |

1xAL2000 or 1xAL3000 |

SK75 |

75 |

10.55 |

1.0 |

2xZ42W |

5.0 |

2x22 |

6.0 |

2xAL2000 or 2xAL3000 |

Some high profiles on the SK air compressors

Minimum pressure valve

Installed at the outlet of the air/oil separator, the minimum pressure valve closes and opens to maintain the air/oil separator at minimum pressure to assure pressure for compressor system lubrication. A check valve closes to prevent air back flow to the compressor at shut down.

(click for larger image)

Cooling fan photo

By using this cooling device, system does not stop even at high temperature, high humidity and harsh working condition. (click for larger image)

TMC gear head

Optimum designed gear head with gear teeth ratio 5(male rotator) : 6 (female rotator) is more efficient than conventional gear ratio 4 : 6

(click for larger image)

LCD monitor

Microprocessor with friendly designed LCD monitor enables full automatic, clear reading and care-free operation.(click for larger image)

PRACTIKO

This up-to-date integrated air/oil separation system minimizes oil in the air to 1ppm and thus greatly enhances the machine reliability and durability. The minimum pressure installed down stream maintains a minimum pressure in the air/oil separator which assures pressure for lubricating the compressor.(click for larger image)

VMC intake valve

Patented VMC intake valve controls compressor capacity steplessly and prevents back flow if the air flow is interrupted when system is shut down suddenly due to unexpected reason (click for larger image)